Precision Machined Plates

Our 40,000-square-foot manufacturing facility utilizes the latest in vertical and horizontal CNC machining technology.

Mold Steel

Materials

National stocks an extensive inventory of the primary holder plate grades. 4140 Pre-hard, P20, 420 Pre-hard stainless, and A36 hot roll. Catering to the mold and die industry, our inventory is carefully selected for perfect yields and minimal scrap loss.

Start a Quote

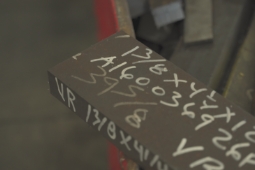

Traceabililty

Each order comes fully traceable back to the melting mill source to ensure quality metallurgy.

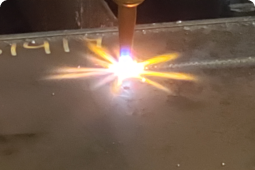

Saw Cut and/or Flame Cut

From large plate saws to multiple cut off saws, National’s cutting department can expedite any material only job quickly. Combining pre-hardened tool steel and hot roll grades offers a single source solution.

Start a Quote

Saw or flame cut to size for the fastest delivery available.

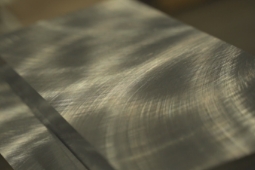

Blanchard Grinding, Planer & Duplex Milling

Custom six-sided plate preparation is completed at industry leading speed. Both Blanchard (rotary) ground and fine milled surface processing are combined with pristine edge milling.

Start a Quote

Blanchard ground material

Trademark swirl pattern ensures flat material ready for production

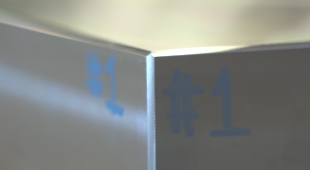

CNC Chamfer options

Save CNC time with National’s machined chamfers. Never beveled or sanded, our machined chamfers are available on all our plates.

Start a Quote

Save time

Machined uniform chamfers save customers valuable spindle time and ensure toolmakers safety.

In-House Gun Drilling

National offers fully CNC gun drilling to your model on any plate job. Deep lines and complete machined side-work and engraving. No prints needed and minimal added lead time. Remove the need for outsourcing, have National provide plates ready for production.

Start a Quote

Dual spindle

Gun drilling allows for both deep lines and side machining in one set up - to your solid model!

CNC Machines

National’s Mold Base facility has numerous horizontal and vertical machining centers to offer both rough machining and tight tolerance finish machining. Knowledgeable pros with decades of industry experience ensure the form fit and function of your design is what you receive.

Start a Quote

Horizontal machining

Allowing roughing efficiency, and perfect alignment on side-locks and additional side machining.

Surface Grinding

Combining CNC automatic grinding and America’s best grinding talent, our in-house surface grinding ensures precision tolerance and flatness on finish ground plates.

Start a Quote

Surface Grinding

After roughing is available on all plates supplied by National!

Assembly

Final review and assembly by seasoned veterans ensure our finished plates and mold bases are completed to your exact requirement.

Start a Quote

Assembly and inspection

Industry professionals ensure form fit and function of all frames.

Packing & Shipping

Packed, Crated, and tracked from our shop to yours. National’s deliveries remain the top value in the U.S.

Start a Quote

Custom Packing

Custom packaging for export is never an issue.